|

| AR XA Turntable Restoration 2 |

| July 5, 2012 |

| This is the second AR XA turntable I decided to do a restoration on.

If you'd like to see the first restoration you can see it here AR XA Turntable Rebuilding. Periodically I still check out eBay to see what's out there. About a year ago I saw this Turntable on eBay and said to myself....this looks like it could be a nice project. I won the auction and got the turntable for $40.00. After receiving it I took one look at it and thought to myself, oh oh this might have been a mistake. The turntable was in horrible shape. The platter had the typical goo crap on it from the disintegration of the original foam pad. The wiring from the tone arm had been torn from the terminal connector under the base. The plinth was a mess and pully had dents in it. The power cord and phono cables were falling apart from age and usage. The base was scratched dinged. In other words there was nothing good about it! I basically flipped a coin to decide if I wanted to spend time on it or throw back on eBay and try to get a few bucks for it. As the coin was flipping and spinning in the air I made the decision...this baby was going to sing again! I never looked to see if the coin was heads or tails. I picked it up and put in my pocket then said, Ok, let's get to work..... You can click on any image to enlarge it. If your interested in more info on the AR XA Turntable here's a few great sites with tons of info and memebers who are more than willing to help if you need it. Audiokarma.org Vinyl Nirvana.com Vinylengine.com |

|

| Here's how the turntable looked when I received it. As you can see it's in terrible shape as I mentioned above. | Another view of the it as I received it.. | And another view.....what a mess! But no sense just complaining about it, let's fix her up! |

|

|

|

| First thing to do is disassemble everything. (This is a photoshopped picture from my first restoration page but the parts are the same) | All the hardware. (This is a photoshopped picture from my first restoration page but the parts are the same) | Front of the base. Few scratches and some black stuff on it. But not in to bad of shape. |

|

|

|

|

| Back side of base. Again a few scratches but not to bad. | First I like to do the work required on the base then put it a side till the end. First step is to mark where we want to install the RCA jacks and power socket. Painters tape works well for this. | Measure half way between top and bottom of the base and scribe a line. Then draw a line where you want the jacks. |

|

|

|

|

| The original power cord was pretty frail so I decided to replace it with a socketed power cord. For the power socket I make a little template for the proper size. Placed it in the center of the base and made a trace. | Drill two small holes in opposite corners | Now use a coping saw and carefully cut out the hole for the power socket. You want to make sure and stay within the trace when cutting. The power socket doesn't have much of a lip so if you cut the hole to big you'll have a gap and it will look like crap. |

|

|

|

|

| Here's how it looks after the rough cut. Try the socket to see if it fits. It probably won't, the hole will most likely be a little to small. You can take a file and file the cut out till the power sockets fits nice and snug. | The original RCA cables were

a mess so I decided to added some RCA jacks in the base and wire the

tone arm to them. Makes life a lot easier without having the RCA

cables hanging from the turntable when moving it around. These are the

drills used to drill the holes for the RCA jacks.

First I used the 5/8" spade drill and drilled

about 5/16" deep. Be careful not to drill all the way through

the base. Then used a 3/8" drill and drilled through the center of the first hole all the way through the base. |

Picture of the RCA

jacks I used. If you notice the plastic washer has a small shoulder on

it. The diameter of the shoulder is 3/8". This helps to keep the jack

centered in the 3/8" dia. hole drilled through the base. I bought the jacks here RCA JACKS |

|

|

|

|

| The bottom cover slides into the slots as seen in the above picture. I don't use that cover so the back of the base has an opening where the cover slide in. Don't like that look at all! | I took a piece of hardwood laying around and cut a piece to fill the opening in the back. | Here's how the back of the base looks with the power socket and RCA jacks installed. The power socket is a three prong socket but the ground isn't used. Also the piece from the previous picture install on the bottom. |

|

|

|

|

| I messed up and forgot to take a picture of the front of the base before assembling the turntable. Anyway here's how the front looks. The "AR inc"badge was missing when I bought the turntable but was able to get one from the seller "vintage ar" on ebay. | I should have ementioned this earlier but I used Howards "Restore and Finish" and "Feedn-Wax" on the base bebore installing the power socket and RCA jacks. This is the best refinishing stuff out there...believe me! | Next step was to restore the metal plinth. It was in bad shape. First I tried sanding and scraping but as you can see it wasn't getting me anywhere. |

|

|

|

|

| Went to Home Depot and bought some good old fashion paint stripper. Brushed on a little bit..waited a minute then tried scraping. I don't know what the coating on the pinth is but it started to come off faster than a prom dress. Within ten minutes the entire plinth was clean. Wow, that was a lot easier than I expected. | After stripping it I sanded

and sanded and sanded till the surface was as smooth as a baby's as*. Then cleaned with acetone. Finally took a clean cloth and buffed it to a shinny finish. I forgot to take a picture when it was finished...sorry about that. |

Final step for the

plinth was to paint it. I wasn't to sure if I should prime then paint or

try some of the new "Rust-Oleum Universal Paint and Primer in one".

I guess I'm a lazy guy and decided to try the "Paint and Primer in one". All I can say is I was very impressed with the "Paint and Primer in one" Three coats and it looked bright, shinny and beautiful! I highly recommend this stuff. |

|

|

|

| Now we'll work on the platter. What you see is very typical of these turntables. What happens is the foam pad originally supplied by AR degrades into a sticky mess when stored for many years in a basement or some other moist area. Removing it is a work of love. What I did first was use a scraper to get most of the junk off. Then took some 240 grit sandpaper and sanded the hell out of it. The biggest problem is the sandpaper fills so quickly from the sticky goo and aluminum from the platter itself.....what a mess! | The next two steps probably

won't be an option for most people. Took the outer platter to work and placed it on a lathe. Then used lots of scotch brite while the platter was spinning in the lathe. This worked quite well. Removed almost all the remianing crap while giving the platter the "Spun" aluminum look. |

The inner platter on the lathe for the same method of removing the messy crap. |

|

|

|

|

| Here's how the platter looked when done. Didn't get it new looking but good enough for me. | The "T" bar was in good shape and didn't need much work other than cleaning out the two wells and replacing the foam washer on top of the platter spindle well. You can see the old foam washer has pretty much disintegrated. | I had some green felt laying around so I made a washer to replace the disintegrated old foam one. Before installing the platter I put about 10 drops of sewing machine oil on it. |

|

|

|

| The three springs that hold the "T" bar in position were in good shape. I know some people recommend replacing them but I felt these were still ok to use. Used a wire wheel on the grinder to remove the glue used to hold them in place on the "T" bar. Probably the easiest part of the whole restoration. | These are the three rubber

washer / bushing that mount on the bottom of the springs. The original

foam has taken the shape of the spring coil. I probably could have

still used the foam but figured while everything is apart might as well

replace them. I've heard some say you don't need the foam, I'll leave that up to you... your choice. |

Had some half inch

foam laying around, (I know it's pink but that's all I had so don't give

me a hard time about it!) Took two washers approximately the diameter I needed and placed one on each side of the foam. Squeezed them together then took a pair of scissors and cut around the washer. |

|

|

|

|

|

Here's how they

came out. Not perfect but should work fine. Folded the foam in half and made a small circular cut, that gives the hole in the middle. |

They look a little better once installed in the springs. |

The original studs

have to go. I didn't even bother trying to remove the nuts...wasn't

worth my time. Time to make some new ones. |

|

|

|

|

| These are 10 X 24 x 2" Stainless Steel screws. You can get these from Home Depot or Lowes. | Now you have to cut the

screws to length. You can use a screw cutter or a hack saw to do it. I

tried using the screw cutter but I guess I'm getting to old and don't

have the strength to cut a number 10 screw... getting old really sucks!

I ended up using a hack saw. Place the old stud next to the screw to get the right length. |

Here the new stud, fender washer and wing nut. You'll need three sets obviously. |

|

|

|

|

| Here's the "T" bar assembled to the plinth. Don't worry about any spring adjustment yet, that will come near the end of the project. | Now to tackle the motor. The original motor had about an 1/8" verical play in the shaft as can be seen in this picture and the next one. Know idea how that came about but this motor can't be used that's for sure. | Motor shaft all the way down...about an 1/8" vertical play. |

|

|

|

|

|

This is the Hurst

3001-001 motor. The mounting flange is larger than the original motor

and the shaft is about .250" longer. It comes with the capacitor. |

Picture of the back side of the motor. | The Hurst motor has a larger flange and bolt hole layout. I didn't want to drill new holes in the plinth for the Hurst motor so an adapter has to be made. I took some 1/4" plexiglass and drilled an 3/8" hole in it. Then placed the motor on it and traced the motor flange. |

|

|

|

|

| Took my coping saw and rough cut it out. | Boy, that came out great uh....a cabinet maker I'm not! | Not to worry though. Took out my belt sander and sanded the adapter to it's final shape. |

|

|

|

|

|

Well, that looks a

little better! I maked where the bolt holes had to be drilled. |

After drilling the holes I tapped 4 X 40 threads, | Now I took the original motor and marked the holes. These will be the holes that will line up with hte holes in the plinth. |

|

|

|

|

| After drilling the plinth mounting holes I countersinked the holes so the screwheads would be below the surface, if not the new motor won't set flush on the adapter. | Here's the finished adapter. | You'll need two 4 x 40 Flat Head Machine screws to mount the adapter to the plinth. You'll have to cut them to the proper lenght so they don't protude above the plinth surface. I forgot to measure the length of the cut screws...sorry about that. You'll have to cut them by trial and error. |

|

|

|

|

| I know you're probably

thinking I'm crazy but I painted the ends of the screws black so they'll

match the color of the plinth..... Some people call me anal-retentive...... |

The adapter mounted to the plinth. | The Hurst motor mounted to the adapter with two 1/4" 4 x 40 screws. |

|

|

|

|

|

Now that the motor

is installed it's time to wire everything up. The switch didn't look to good so I figured I'd take it apart and see what's inside....easier to do it now instead of after it's installed. |

To take the switch apart simply take some strong needle nose pliers and bend the four tabs just enough to get it apart. Be careful not to bend them to much or they could snap off. Good thing I decided to do so. The contacts are a mess. | I used the dremel with the little wire wheel to clean it up. Worked very nice as you can see. Before reassembling it put a drop of Deoxit on the contacts. |

|

|

|

|

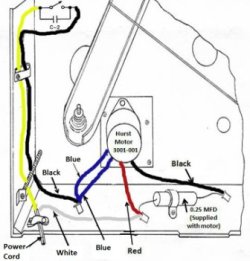

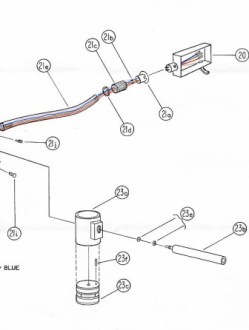

| There, all back together and ready for another forty or so years of use. By the way, it worked like a charm after installing. | Here's how it looks after wiring everything. Certainly not rocket science here. | Here's a diagram of the wiring. |

|

|

|

|

|

Now the real fun

begins.....the infamous AR tone arm damping system! The first thing we

want to do is GET RID OF IT! I'll discuss a little later why. See that little pin sticking out below the screw, that's what I'm talking about. |

To get at the pin you have

to remove the two little screws on either side of the housing (see

previous picture). BE CAREFUL NOT TO LOSE THE TWO LITTLE SCREWS OR

YOU'LL BE SCREWED! The collar holding the brass pivot bearing with the pin will slide out of the housing. Be careful when handling this piece, there's a pivot bearing on each side that you MUST NOT DAMAGE. |

Here's another view of the brass pivot bearing with the pin. You'll notice a "Flat Spot" on either side of the groove. Remember those flat spots, I'll mention them a little late on. |

|

|

|

|

|

We want to remove

that pin. We won't need it any longer. The easiest way I found to remove it is with a strudy pair of needle nose pliers and give it a good yank. Well once again my age is catching up me, I couldn't get that sucker out of there for the life of me.....so on to plan two..... |

Plan two......I placed the pin in a vise at a slight angle with a penny under the brass pivot bearing. The penny was there so I wouldn't cause any damage to the pivot bearing or the outer edge. | A closer view so you can see the pin in the vise. |

|

|

|

|

| With a screw driver I slowly pried the brass pivot bearing upward. | Bingo...plan two worked with no damage to the brass pivot bearing. |

There you go. Pin

safely removed and again no damage to the brass pivot bearing. |

|

|

|

|

|

Now that the pin is

removed we want to inspect it for any damage. You can see a bunch of

little holes and nicks. Those are from the pivot screw being tightened

up and not lined up correctly with hte pivot bearing. The pivot screws

are steel so fortunately there shouldn't be any damage to them. The pivot bearing itself looks to be in good shape still. The one on the opposite looked good too. |

These are the two pivot

screws that hold the Brass Pivot Bearing in place. They look pretty good. The point is still pointed and the bearing surfaces ( the angled sides) are smooth with no grooves in them. As far as I can tell they're a # 2 cone point screw, but again make sure not to lose them. I don't think it a standard size you can buy anywhere. |

Just cleaning them up a little with some scotch brite. |

|

|

|

|

|

The Brass Pivot

Bearing was pretty dirty so I wanted to clean it up. I decided to

use the dremel with a buffing wheel attachment. I wanted to make sure I

didn't buff to much and reduce the outside diameter of it. I didn't

think buffing would remove much material so I took an measurement of the

OD before buffing. It measured .618" |

Here it is after the buffing. Looks pretty good. |

Now to verify I

didn't remove to much material I remeasured it.....618". Perfect! Now we can put it aside till we need to reassemble the tone arm. |

|

|

|

|

|

I think this part

is important for real improvement on this turntable. The spindle that screws into the tonearm originally had a little foam washer and a plastic washer on the top. If you don't see the little foam washer, don't worry about it. It probably disintegrated about the time Lewinsky was.....well you know! This was the tonearm damping system. These washers rested against the brass pivot bearing in the tonearm assembly. As the tonearm was lifted up then lowered on to the record these washers would rub against the brass pivot bearing slowing down how quickly the tonearm would descend. And if by accident you dropped the tonearm it wouldn't come crashing down and possibly damag your stylus! From what I've read it's best to remove these washers and don't worry about having a damping system. |

In case you forgot here's

the flat spots again... Above is the brass pivot bearing. The two inner shoulders is where the plastic washer on the spindle rubbed against for the damping system. If you click on the picture you see a small flat spot on the bearing. This is where the washer would line up when the tonearm was playing a record. There wouldn't be any contact at this point between the washer and the bearing......and the damping system was disengaged. It worked great in theory but we don't need or want it. |

Here's the foam and

plastic washer removed from the spindle. |

|

|

|

|

|

As you can see the

knurled part of the spindle is pretty dirty so we want to clean it up. I tried a old tooth brush first but it didn't relly do much. Got to find a better way to clean it. |

Took out the dremel and the wire

wheel and gave that a shot. Worked great. |

Next I wanted to

clean up the bearing surfaces of the spindle. Again the dremel with the bushing wheel worked nicely. I was afraid this time of removing any material with this method. I proved earlier when buffing the brass pivot bearing it doesn't remove enough if any to worry about. |

|

|

|

|

|

Here's how it looks

after cleaning. If you notice right in the threads is a small gray plastic piece (red arrow pointing at it). It's a locking system. Original with the damping system you wouldn't tighten the spindle all the way. If you did the tone arm would bind and not move at all. You'd have to play with tightening spindle till the damping system was working. That little gray piece would hold the spindle in place and not allow it to loosen. Again, another reason to get rid of the damping system. |

The threaded collar that holds the headshell intact also need to be cleaned. Used the dremel and wire wheel again. Works great. You can see in the picture where the top half of the collar has been wired wheeled. |

The housing for the

bearing assembly needed cleaning to. The little wire wheel didn't have the power to do much so I decided to use my bench grinder wire wheel....plenty of power now! |

|

|

|

|

|

You can see it

cleaned it up nicely...except the brushed aluminum look is gone! This isn't acceptable, I wanted the original brushed aluminum look. |

Ok the brushed aluminum look

is back. I took some 180 grit sandpapper and put a piece of wood across it. Holding the housing against the piece of wood I carefully slid it back and forth till I got the brushed aluminum look I wanted. Don't try to sand it free hand, you'll never get it right....believe me it tried it! Unfortunately the picture doesn't do it justice. |

Now we get into the

fun part.....rewiring the tone arm. This is the part that will make or

break this project! First thing you'll notice when the collar is slid back is a "RED" marking. Remember this is the top when reassembling. |

|

|

|

|

|

How to remove the

plastic piece from the tone arm tube. This is a little trick I learned

from Scott Hamrick who has a page on Vinyl Nirvana.com

"How to rewire a AR XA tone arm" Thanks Scott, nicely done. I placed a 19/64" drill bit into the plastic piece then with a strudy pair of needle nose pliers I gently twisted and pulled at the same time. There's two little dimples inside the tube that hold the plastic piece in. With a little patience the plastic piece will pop out. AAgain, be very careful in this step, if you ruin the plastic piece you have to jump on eBay and buy another TT just for that part. |

Here's the plastic piece when removed. You can see the scoring on the side from rubbing against one of the dimples while removing it from the tube. | You'll notice after removing the plastic a little washer with two indents. That's what holds the threaded collar from sliding to far back on to the tone arm tube. Make sure when reassembling those two indents sit on the two steps on the plastic piece,(two black marks on the plastic piece in the picture).If the two little steps aren't marked take a black magic marker and mark them, This will help to see them when reassembling. |

|

|

|

|

| This is how it should look when put back together. It's hard to tell from the picture but the two indents are sitting on the the steps. | When removong the old wires the solder will probaly stay in the little connector pins. I found using a small pin and pushing it in the pin while heating it up will give you an opening for the new wire. |

Ok, you're probably

wondering why a picture of a computer fan..... I racked my brain as to what I wanted to use for the tone arm wire. On the last rebuild I used the Cardas 4 X 33 shielded cable. That wire had to have the shielding removed and the four internal wire were used. I didn't want to go that way again, besides it's a little pricey. I had to find some very thin wire....33 gauge or less. Then it dawn on me, if I could fine a small motor the armature wire would probably be small enough. That's where the computer fan came in. |

|

|

|

|

| Here's the original tone arm wire. It measures .007"(33 ga.). | Here's the armature from the

computer fan. The wire measures .005" (36 ga). This will work fine. Gonna have to be real careful with this stuff though, it's pretty damn fragile to say the least. |

To give a

comparison the above picture is a human hair...it's measures just over

.004" ! Pretty small stuff we're working with. |

|

|

|

|

|

Next I unwound

about ten feet of the wire from the armature and cut in four pieces. The picture above compares the four strands of armature wire to one strand of the Cardas wire. |

Next step was to take two

strands and wind them together. This will give a little more strength. I put the two wires in a small vise then the other ends of the wires in a hand drill. Slowly ran the drill till the two wires were twisted around each other. Again, have to be very careful not twist to tight or you'll snap the wires. It's hard to see the wires in the picture but believe me they're there. Did this operating twice. One set for each channel. |

Now you have to tin

one end of each wire. The wire has an enamel coating on it which

can be burned off while tinning if your soldering iron is hot enough. You'll need to use a good size soldering iron. |

|

|

|

|

|

All four wires

soldered. You'll want to use a small soldering iron here and be quick, you don't want to melt the plastic piece. |

Now we're ready to reassemble the tone arm. Here's a picture from the AR XA service manual that show the assembly | We're getting there. You can see the two sets of wires coming out of the tube. |

|

|

|

|

| Now the tube is installed into the housing. It's hard to see but the wire are there. | A little nail polish to hold the wires in the channel at the bottom of the housing. |

Now for the tricky

part. I wanted to make sure the wires wouldn't rub against the housing in fear it would rub the enamel off the wires eventually and cause a short. So, I stripped a small piece of the insulation off some 18 ga wire and slid the 4 wires though it. Then took another piece of the armature wire and attached it to the grounding lug then wrapped it around the little piece of insulation to hold it in place. The piece of insultaion is just above the housing so the wires won't hit it. You'll have to look at the picture to see what I mean....hope you can figure it out. |

|

|

|

|

| Finally I took the piece of wire from the grounding lug and wrapped around the other 4 wires. This should hold the 4 wires together and hoprfully act as a ground. | Now we can go ahead and

assemble the rest of the tone arm. I should mention I used a Q-tip with some sewing machine oil to oil the brass pivot bearing before installing it. Also be careful when lining up the two pivot screws with the pivot bearings. Make sure they're in place before snugging them. And make sure everything is centered in the housing. The spindle can be tighten snug now that the damping system has been removed. Just snug the pivot screws till there is minimal wobble in the housing. |

Now we can install

the tone arm into the well. There's a small ball bearing (.219"

diameter) that goes into the well first. Guide the wires through the rubber grommet in the plinth while lowering the spindle into the well. You'll have to tilt up the turntable to grab the wires underneath. Ok that's done....whew! |

|

|

|

|

|

Flip up the

turntable and wire the RCA jacks. I used a meter to find out what wires had to go to each jack. And added the ground from the "T" bar. That completes all the wiring....let's hope it works! |

This is how the wires look

going through the plinth. I'm sure some people will say the wires are much to small and fragile and they will eventually fail. I guess only time will tell that. After finishing the tone arm installation what you want to do is to make sure the wires aren't creating any drag on the tone arm. The easiest way to check for this is to balance the tone arm at 0 grams with the headshell/cartridge and counterweight install. You should be able to take the tone arm and place it anywhere and when you let go it should stay right where it is. If not, you've got to find out whats causing the problem. Unfortuntely you'll have to do that on your own.... This tone arm did not move a bit when I let go...so we're in good shape and ready to move to the next step. |

Forgot to mention the brass counterweight. It only needed a quick cleaning with some scotch brite. |

|

|

|

|

| Nice bright and shinny now. | We now want to put the

pulley back on the motor shaft but we have a problem here. The pully is

very dirty and has some dents on it. The owner before me sure didn't

take care of this thing. It shouldn't be a big deal to straighten it out and clean it up. |

That's a little

better. Still has some stuff in the crowns of the pulley but I

don't want to do much more to it in fear of removing to much material

and change it's diameters. This will do! You can now put the pulley on the motor, we'll adjust the height later |

|

|

|

|

|

Now you can put the

platter on. You'll want to adjust the three springs underneath till the

distance between the bottom of the platter and the plinth is equal all

around. Mine looks a little off in the picture but it's fine. |

After you get the springs adjusted gently lift up the turntable and put some nail polish on the wingnuts and threads to hold them in place. |

Next we want to

prepare the belt for installation. You should probably get a new one

from eBay, they're about $10.00. AR recommended that the belt be bathed in Talc powder yearly. This provides a little belt slippage on start up and reduces the torque on the motor. I bought some Johnson's baby powder. It's talc with a little stuff added for the perfume affect. Besides, who doesn't want their new TT smelling baby fresh! |

|

|

|

|

|

Next step is to pour a tiny bit of the baby powder in a baggie then

throw the belt in. Now do the old "Shake n' Bake" trick. |

After

removing the belt from the baggie shake off the excess powder. The belt

should look like this.After removing the belt from the baggie shake off

the excess powder. The belt should look like this. Now install the belt on the TT. |

Place the belt on

the upper section of the pulley (this is for 33 1/3) and the over the

inner platter. Next place the outer platter on top of the inner platter upside down. Now you can see if the belt is aligned properly while running. As you can see it's running right in the center of the pulley exactly where you want it. |

|

|

|

|

|

Ok, we're almost

done! (The cartridge I decided to use is the AT440MLa. I had read a lot of very positive reviews about this cartridge and for the price it seemed like a good deal!) After everything was assembled and ready to go I noticed the cartridge wasn't sitting parallel to the record surface. This called VTA, (Vertical Tracking Alignment). In the picture if you click on it you'll notice the tail end is sitting much closer to the record that the head of the cartridge. Some people say this cartridge performs better with the tail end down but this is a little excessive. |

AR used to supply a little

hard cardboard shim that could be placed between the cartridge and the

head shell (in the front) to compensate for this problem. Of course that

little piece didn't come with the turntable. No problem. Just cut a little piece wood to do the same thing. Depending on the cartridge you use you'll have to play with the thickness of the wood shim. |

Here's what it

looks like with the shim in place. You'll have to use a little trial

and error to get the shim in the proper location to suit your

cartridge. As you can see mine is about a 1/8" from the front surface. The other thing you'll notice is you can't see much of the screw heads. I don't know if your cartridges will mount the same way or not. Either way you'll need a VERY SMALL slotted screw driver to install the screws. And remember.....just snug them up. If you over tighten them those damn little brass inserts will start spinning and the next thing you'll find yourself running to eBay for another head shell....and if your lucky you'll get one for under $50.00!!! |

|

|

|

|

|

Here's a close-up

of how the cartridge sits now. Almost parallel to the record surface.

The tail is maybe sitting a tiny bit lower but like I mentioned early a

lot of people say this is the preferred position, (VTA) for this

particular cartridge. Tracking performance and sound quality is fantastic in this position......I'm going to leave right where it is. |

After installing the shim it

was time to reset the tracking force. I like 1.75 grams for this

cartridge....1.742 grams is close enough for me. After all, the brass counter weight isn't the easiest thing to play with on this TT! |

Coming Later |

|

|

|

|

|

This headshell is a

spare one I've had laying around. When I bought it it had two missing

wires so I put on the shelf and figured one day I'll get around to

fixing it, if I can I'm not using it currently but figured I'd add the . following pictures because I've had people ask me if the headshells can be rewired. Not an easy job..... |

I put the headshell in my small bench vise pushing in the pin I want to work on. You can see the bottom pin is inside the jaw. |

If you click on the

picture you'll ba able to see the bottom pin is sticking out making it a

little easier to work on. The red wire was the first wire I did, looks like I did a lousy job on it so I'll fix it later. |

|

|

|

|

|

Before you attemp

to solder this pins you need to put a heat sink on them or there's a

good chance the melt housing that holds the pin. If you do that your

screwed. I took a small alligator clip and bent the tip so it would fit in between the bottom and top pins. (If your working on a top pin you won't have to bend it.) |

Fits nicely between the pins. |

Use a very small

soldering iron tip and tin the pin...you'll see that in the next

picture. You'll want to get in and out quick, don't let the pin get to hot. |

|

|

|

|

|

The pin has been

tinned and ready to have the new wire soldered in. The reason for doing this step is it will make easier when soldering the wire. You'll also want to tin the wire before installing. |

Now all you have to do is

hold the wire in the pin and hit it with the soldering iron.....presto

done! That was easy! I also fixed the red wire while doing htis. |

Finally I put a

small piece of shrink tubing over the connection. This will help to

prevent the wire from breaking at the solder joint in the future from

any bending when installing the cartridge. The picture doesn't show it but I put shrink tubing on all four connection before finishing. I haven't soldered on the phono clips yet so I can't show that part of it. But that part should be easy. |

|

|

|

| Finally got around to

getting the phono clips, These are pretty nice clips. "J.A. MICHELL PREMIUM PHONO CARTRIDGE CLIPS" I got them of ebay for $20.00. |

Clips installed. | Cartridge installed with

clips attached. I had to put the little piece of wood under the cartridge again to get the cartridge properly aligned. |

|

|

|

Here's a needle drop so you can hear how it sounds. I Ain't Superstitious By Jeff Beck |

|

Ok, it's all

together and ready for a test drive....can't wait to hear baby sing! I'm quite happy with the outcome so far. |

Picture showing the connections in the back | The End. |

|

|

|

|

| Thought I'd show a picture

of each of the three AR XA's I've done so far. This is the first one I did back in 2009. |

This is the second one. This page is about restoring this one. | This is the third one I

finished recently, (10/2012). I decided to try a light color for

the plinth this time. I didn't bother putting another web page together for this one. I don't think I could of added anything new to the restoring process for the XA that isn't on this page or my first one. |

Ok, now for the results......... was it worth all that screwing around???? For the second time doing this it was worth it!!!! This AR XA sounds just as wonderful as the first one I did. Without a doubt these turntables are one of the finest out there. I didn't included every little detail of the restoration but I hope I included enough to help anyone interested in restoring one of these wonderful turntables! Plus there's tons of other sites out that show some unbelievable restorations and modifications to the AR XA turntable. I hope you enjoy yours as much as I'm enjoying mine. And thanks for looking...... John |